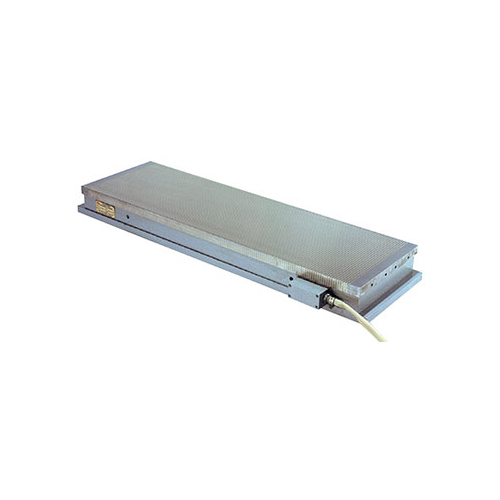

UNIROW Single Row EP-M Chuck with Square Poles 50mm, 75 mm

UNIROW Single Row EP-M Chuck with Square Poles 50mm, 75 mm Specification

- Voltage

- No power required during operation, only for magnetization/demagnetization - typically 110V/220V

- Surface Finish

- Precision ground, corrosion-resistant top surface

- Power Supply

- External Electronic Control Unit (for ON/OFF)

- Magnet Grade

- NdFeB (Neodymium-Iron-Boron) high grade

- Composite

- High-quality steel body with high-energy square permanent magnets

- Power

- Extremely low power, only during magnetization/demagnetization

- Application

- For holding ferromagnetic work pieces during precision grinding, milling, and EDM machining

- Frequency

- 50/60 Hz (for magnetizing control unit)

- Material

- Alloy steel body with brass and steel top plate

- Product Type

- Single Row EP-M Chuck with Square Poles

- Magnet Category

- Electro Permanent Magnetic Chuck

- Magnet Type

- Rare Earth Permanent Magnet

- Shape

- Rectangular/Square single row design

- Size Range

- Standard lengths: 200 mm to 1000 mm, width: 150 mm to 300 mm

- Weight

- Varies by size; example: approx. 95 kg for 600x200 mm

- Color

- Silver Body with Black/Yellow Pole Top Pattern

- Usage & Applications

- Grinding, Milling, EDM, CNC machining operations for heavy-duty ferromagnetic components

- Capacity

- High clamping force, up to 16 kg/cm

About UNIROW Single Row EP-M Chuck with Square Poles 50mm, 75 mm

Jump on the opportunity to own the UNIROW Single Row EP-M Chuck with Square Polesone of the most hot-selling, rare earth magnetic chucks engineered for heavy-duty precision. Crafted from top-notch alloy steel and fitted with wondrous NdFeB magnets, this blue-ribbon chuck offers staggering lifting force up to 1700 kg. It features low-residual magnetism for easy workpiece release, robust insulation, and a dry-operation design with no special cooling required. Be it CNC machining, grinding, or EDM, this magnet delivers international-standard safety and reliability, conforming to ISO/CE norms.

Outstanding Features & Versatile Applications

The UNIROW Single Row EP-M Chuck stands out with its high clamping force, precision-ground and corrosion-resistant top plate, and rare earth NdFeB magnet technology. Designed for robust ferromagnetic holding during grinding, milling, and EDM, it supports heavy-duty machining with ease. The electro-permanent technology enables both manual and automated switching, making it a superior choice for modern workshops seeking streamlined, reliable clamping solutions.

Supply Capability, Sample Support & Export Markets

UNIROW ensures steady supply ability for both standard and custom chuck sizes. Samples are available for quality evaluation upon request. Our commitment to careful packaging and efficient logistics guarantees safe transit and prompt order processing. With an established presence as exporter, manufacturer, and supplier in India, UNIROW commands strong export market share across Asia, Europe, and the Middle East, serving both small machine shops and large manufacturers.

Outstanding Features & Versatile Applications

The UNIROW Single Row EP-M Chuck stands out with its high clamping force, precision-ground and corrosion-resistant top plate, and rare earth NdFeB magnet technology. Designed for robust ferromagnetic holding during grinding, milling, and EDM, it supports heavy-duty machining with ease. The electro-permanent technology enables both manual and automated switching, making it a superior choice for modern workshops seeking streamlined, reliable clamping solutions.

Supply Capability, Sample Support & Export Markets

UNIROW ensures steady supply ability for both standard and custom chuck sizes. Samples are available for quality evaluation upon request. Our commitment to careful packaging and efficient logistics guarantees safe transit and prompt order processing. With an established presence as exporter, manufacturer, and supplier in India, UNIROW commands strong export market share across Asia, Europe, and the Middle East, serving both small machine shops and large manufacturers.

FAQs of UNIROW Single Row EP-M Chuck with Square Poles 50mm, 75 mm:

Q: How does the actuation system work in the UNIROW Single Row EP-M Chuck?

A: The actuation system uses electrical activation for magnetization and demagnetizationno power is required during operation, only during switching. You can choose manual or automated switching as per your needs.Q: What are the main benefits of using this electro permanent magnetic chuck?

A: This chuck provides a high clamping force with low residual magnetism, allowing quick and easy workpiece release, enhanced safety, and robust performance for precision machining tasks.Q: Where can the UNIROW Single Row EP-M Chuck be used?

A: Its ideal for precision grinding, milling, EDM, and CNC machining of heavy-duty ferromagnetic parts, making it suitable for tool rooms, production lines, and specialized machine shops.Q: What is the process for ordering and delivery?

A: Orders are processed swiftly with secure packaging to ensure safe transport. Logistics are managed efficiently for both local and international deliveries, and sample units are available for inspection before bulk orders.Q: How does the UNIROW chuck ensure safety and compliance?

A: The chuck is built to meet ISO/CE safety standards, featuring excellent insulation resistance, a durable steel body, and robust construction to ensure safe and reliable operation.Q: When is power needed for the UNIROW Electro Permanent Magnetic Chuck?

A: Power from the control unit is only needed during the magnetization or demagnetization process; no electrical supply is required during holding, ensuring energy efficiency.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Rectangular Magnetic Chucks Category

EGRIP Universal Cross Pole Rectangular Magnetic Chuck

Price 80000.0 INR / Piece

Minimum Order Quantity : 1 Number

Magnet Category : Other, Electro Permanent Magnetic Chuck

Voltage : 110215 Volt (v)

Color : Silver

EFINE Fine Pole Rectangular Electro Magnetic Chuck

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Magnet Category : Permanent Magnets

Voltage : 220 Volt (v)

Shape : Rectangle

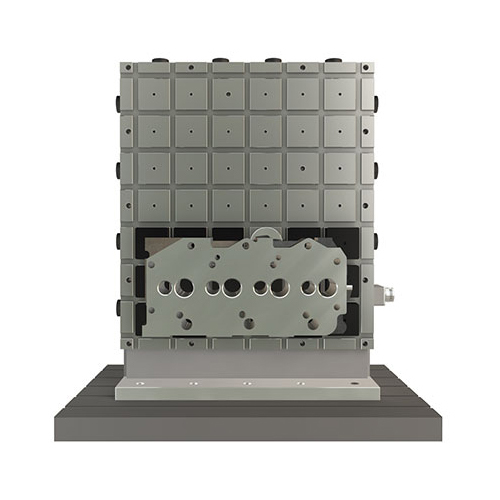

EPCUBE Square Pole Tomb Type Electro Permanent Magnetic Chuck

Minimum Order Quantity : 1 Piece

Magnet Category : Permanent Magnets

Voltage : 220/380/400/480 Volt (v)

Shape : Rectangle

Color : Silver

UNIROW Single Row EP chuck

Minimum Order Quantity : 1 Piece

Magnet Category : Permanent Magnets

Voltage : 220/380/400/480 Volt (v)

Shape : Rectangle

Color : Silver

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese